Navigating the Magnetic Mazes & Radio Riddles of EN61000-4-6 & EN61000-4-8

12th September 2023Share This Post

Share This Post

In the realm of power conversion products, compliance with standards is paramount. With the emergence and evolution of the EN61000 series, power supply designers and integrators have a robust framework for ensuring the electromagnetic compatibility (EMC) of their products. This paper will continue our look into these standards with a deep dive into EN61000-4-6 (Conducted disturbances induced by radio-frequency fields) and EN61000-4-8 (Power frequency magnetic field immunity), exploring their significance and applications in power supply design and integration.

EN61000-4-6: Conducted Disturbances, Induced by Radio-Frequency Fields

Overview

EN61000-4-6 addresses the immunity of electrical and electronic equipment to conducted disturbances induced by radio-frequency (RF) fields. This standard aims to ensure equipment operates as intended when exposed to RF disturbances, often originating from devices like two-way radios and mobile phones.

Relevance to Power Supply Design

For power supplies, maintaining stable operation in the presence of RF disturbances is crucial. Power conversion products can be both a source and a victim of RF interference.

Source: Without proper design, power supplies can emit RF disturbances, potentially affecting nearby equipment.

Victim: Power supplies need to function efficiently and reliably when RF disturbances are present.

Designers need to consider RF filtering, appropriate shielding, and component selection to ensure compliance with EN61000-4-6.

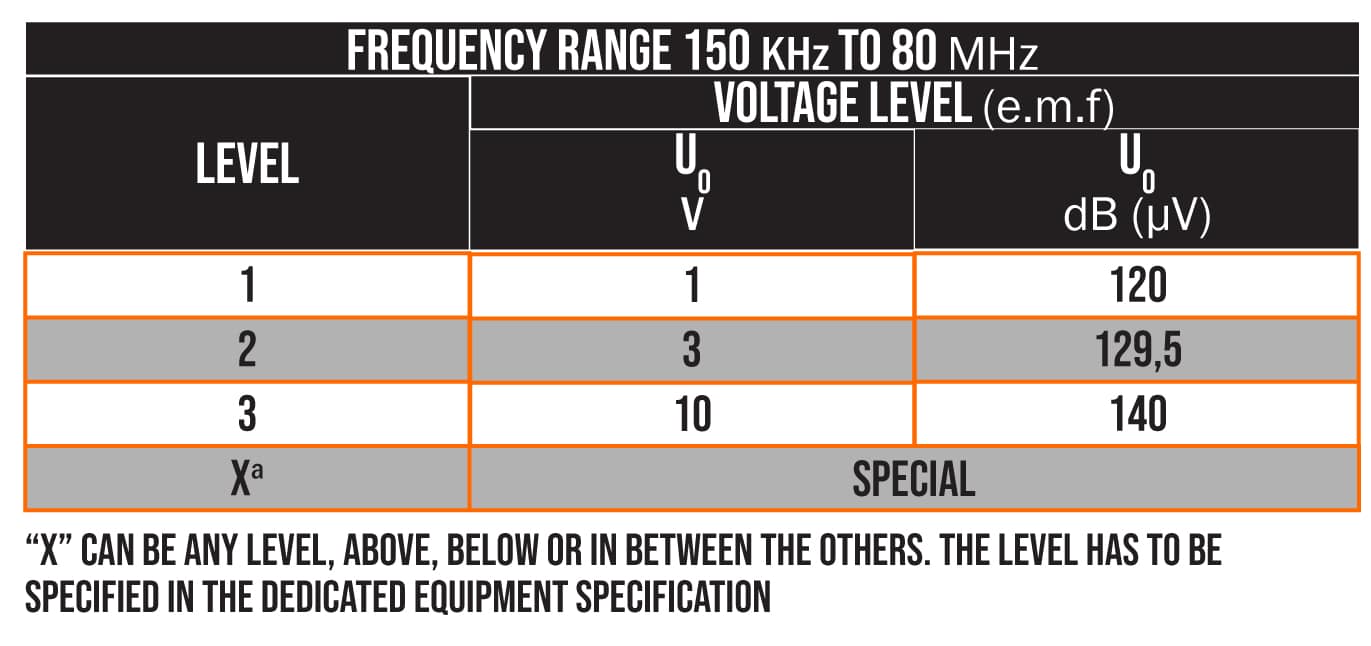

EN61000-4-6 Test levels

Class 1

Low-Level Electromagnetic Radiation Environment

The typical level where radio and/or television stations are located at a distance of >1km and the typical level for low power transceivers.

Class 2

Moderate Electromagnetic Radiation Environment

Low power portable transceivers (typically <1W rating) are in use, but with restrictions on use in close proximity to the equipment. A typical commercial environment.

Class 3

Severe Electromagnetic Radiation Environment

Portable transceivers (2W and more) are in use relatively close to the equipment, but at a distance not less than 1m. High-powered broadcast transmitters that are in close proximity to the equipment and ISM equipment may be located close by. A typical industrial environment.

Class X

X is an open immunity test level that can be agreed and recorded in the respective product standard or device specification.

EN61000-4-8: Power Frequency Magnetic Field Immunity Test

Overview

EN61000-4-8 deals with the immunity of equipment to magnetic disturbances at power frequencies (typically 50/60 Hz). It outlines testing methods and immunity levels for devices and equipment exposed to continuous and short-duration magnetic disturbances.

Relevance to Power Supply Design

Power supplies, by their very nature, can produce magnetic fields, especially in products with transformers or inductive components. Additionally, they might be installed near other devices emitting magnetic disturbances.

Source: Power supplies with transformers or other magnetic components can be sources of magnetic disturbances, especially if not properly designed or shielded.

Victim: A power supply’s performance might degrade in the presence of external magnetic fields.

Complying with EN61000-4-8 involves considering the physical design and layout of power supply components. Effective shielding, careful placement of magnetic components, and design practices that minimize magnetic emissions are essential.

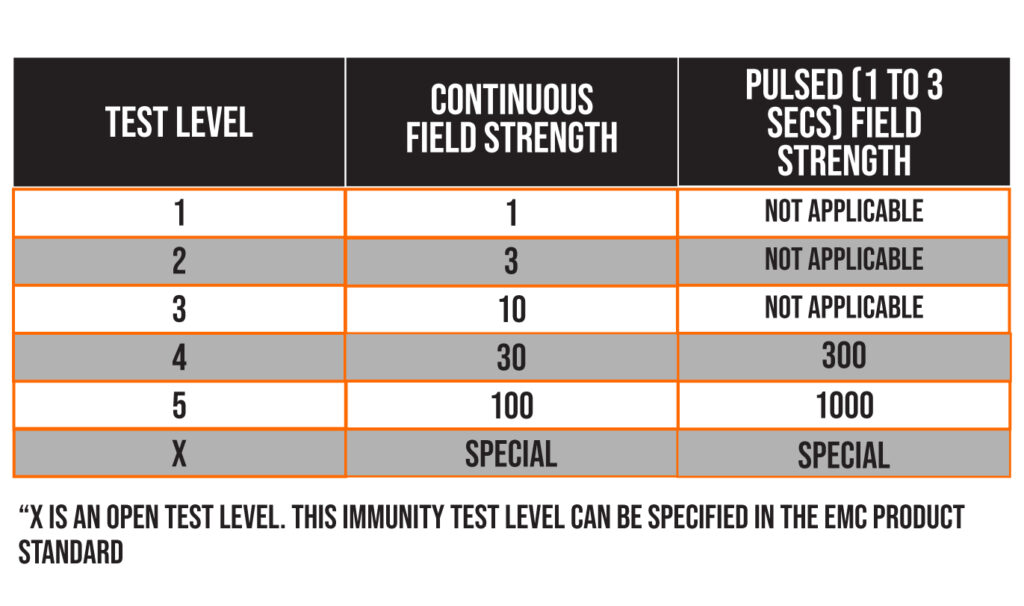

EN61000-4-8 Test Levels

Class 1

Environmental Level

The environmental level where sensitive device using electron beam can be used. Examples include environments containing CRT monitors or an electron microscope.

Class 2

Well-Protected Environment

Examples include households, offices, and hospitals.

Class 3

Protected Environment

Examples include commercial areas, small industrial plants, or a computer room of a high voltage sub-station.

Class 4

Industrial Environment

Examples include heavy industrial plants, power plants, or the control room of a high voltage sub-station.

Class 5

Severe Industrial Environment

Examples include the switchyard of heavy industrial plants, or medium voltage and high voltage power stations.

Ensuring Compliance

To ensure compliance with both standards, a systematic approach is crucial:

Awareness

Begin with a thorough understanding of both EN61000-4-6 and EN61000-4-8, their requirements, and implications.

Component Selection

Choose components that have sufficient voltage and current ratings to withstand the expected transients. Select components with fast response times and low parasitic capacitance and inductance. Relec Electronics will help you in this regard.

PCB Layout

Optimize the PCB layout to minimize the loop area of sensitive traces. Separate high-voltage and low-voltage circuitry and ensure proper grounding techniques to reduce the impact of transients.

Filtering and Decoupling

Incorporate appropriate filters, such as transient voltage suppressors (TVS), RC snubbers, and line filters, to attenuate transient voltages and prevent them from reaching sensitive circuitry. Use decoupling capacitors to stabilize power supply voltages.

Shielding and Grounding

Implement effective shielding techniques to minimize the coupling of transients. Use proper grounding techniques, including star grounding, to maintain a low impedance path for transient currents.

Testing and Verification

Implement effective shielding techniques to minimize the coupling of transients. Use proper grounding techniques, including star grounding, to maintain a low impedance path for transient currents.

Related Content

Continuing our look at the EN61000 series of immunity standards, this month we’re going to give you 2 for the price of one…

Conclusion

The EN61000-4-6 and EN61000-4-8 standards play pivotal roles in ensuring that power conversion products remain immune to RF and magnetic disturbances, respectively. As power supply designs become more intricate and as the electromagnetic environment grows more challenging, understanding and adhering to these standards is more crucial than ever. At Relec Electronics, we pride ourselves on keeping abreast of evolving standards, ensuring that our power supply solutions are at the forefront of compliance and performance.

SHARE

sign up for our newsletter

Enter your email address below

LET’S MAKE THIS EASY. CALL 01929 555 700

why choose relec?

-

Faster

Our aim is to get back to you with an initial response within the hour.

-

Attention to detail

We pride ourselves on getting you the right product, at the right price and on time.

-

New ideas

We are constantly looking for latest technology and products for your applications.

-

Beyond standard

It’s not just about the product. Our service goes way beyond the norm.

-

Easy

We want to make your life as simple as it can be. Call us to find out what we can offer.