20W Turnkey Solutions for the Railway Industry

14th May 2021EC7BW18-ECRT/EDRT Series – 20W Turnkey Solutions for the Railway Industry

One size fits all has always been a goal for power supply manufacturers, and thanks to the use of the latest technology, Relec electronics are pleased to announce the release of Cincon’s EC7BW18-ECRT/EDRT 20W universal input DC-DC Converter especially designed for the Railway Industry, available in chassis and Din-rail mount formats. The EC7BW18-ECRT/EDRT series requires no additional components and meets the requirements of EN50155, EN50121-3-2 & EN45545-2 out of the box, providing turnkey solutions for system designers.

One of the biggest design challenges for power supply manufacturers in a worldwide rail industry is that train-borne applications around the world have different battery voltage parameters across different vehicle classes. Table 1 below summarises the different supply voltages seen across the industry along with short term fluctuation ranges.

| Table 1: EN50155 Input voltage range | |||

|---|---|---|---|

| Nominal Input Voltage (Vin) | Continuous Voltage Range (0.7*Vin-1.25*Vin) | Fluctuation Voltage Range | |

| 0.6*Vin (0.1S) | 1.4*Vin (1S) | ||

| 24V | 16.8V - 30V | 14.4V | 33.6V |

| 36V | 25.2V - 45V | 21.6V | 50.4V |

| 48V | 33.6V - 60V | 28.8V | 67.2V |

| 72V | 50.4V - 90V | 43.2V | 100.8V |

| 96V | 67.2V - 120V | 57.6V | 134.4V |

| 110V | 77V - 137.5V | 66V | 154V |

Cincon’s EC7BW18-ECRT/EDRT solutions have an input range of 10 to 160V meeting all of the above in a single unit. In addition to the above units will also meet the requirements of RIA12 surge A (3.5 x Vin for 20mS) for 24V and 52V systems.

Definition of Turnkey Solution

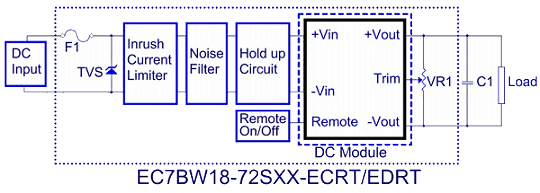

Figure 1 below shows the internal structure of EC7BW18-ECRT/EDRT. The series has been designed to be compliant to EN 50155, with built in with inrush current limiter, hold-up circuit, and EMC solution to EN5021-3-2 in a single chassis or din-rail mounted package.

Compliance to EN50155

In order to be EN 50155 (Electronic Equipment for railway applications – rolling stock) compliant, a device must pass a number of type tests relating to temperature, humidity, vibration, shock, and electrical tests (See Table 2). These simulate the harsh environment seen in train-borne operation.

| Table 2: EN50155 List of tests | |||||

|---|---|---|---|---|---|

| Test | Type | Test | Type | ||

| 1 | Visual Inspection | M | 8 | Cyclic damp heat test | M |

| 2 | Performance test | M | 9 | Salt mist test | O |

| 3 | Power Supply test | M | 10 | Enclosure protection test (IP code) | O |

| 4 | Insulation test | M | 11 | EMC test | M |

| 5 | Low temperature storage test | O | 12 | Vibration and shock test | M |

| 6 | Low temperature start-up test | M | 13 | Equipment stress screening test | O |

| 7 | Dry heat test | M | 14 | Rapid temperature variation test | O |

Tests marked ‘M’ are mandatory. Tests marked ‘O’ are subject to contract agreement between the user and the supplier.

The EC7BW18-ECRT/EDRT series have been shown to be compliant for all of the above tests under all input voltage ranges highlighted earlier in Table 1.

Inrush Current Limitation

In order to meet the power supply tests highlighted above, a turnkey solution has to be able to provide “hold up” of the output for a period of time after the input supply disappears. This can be done simply by adding capacitance at the input side. However, the transient characteristic of a capacitor will cause higher inrush currents at the input side during switch on. If there is no action to restrain the inrush current, it can result in a voltage drop of the front-end of the converter (Input voltage < Vin min) or trigger the over-current protection of the input circuitry, leading to no output from the converter.

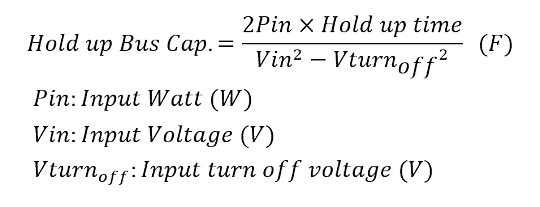

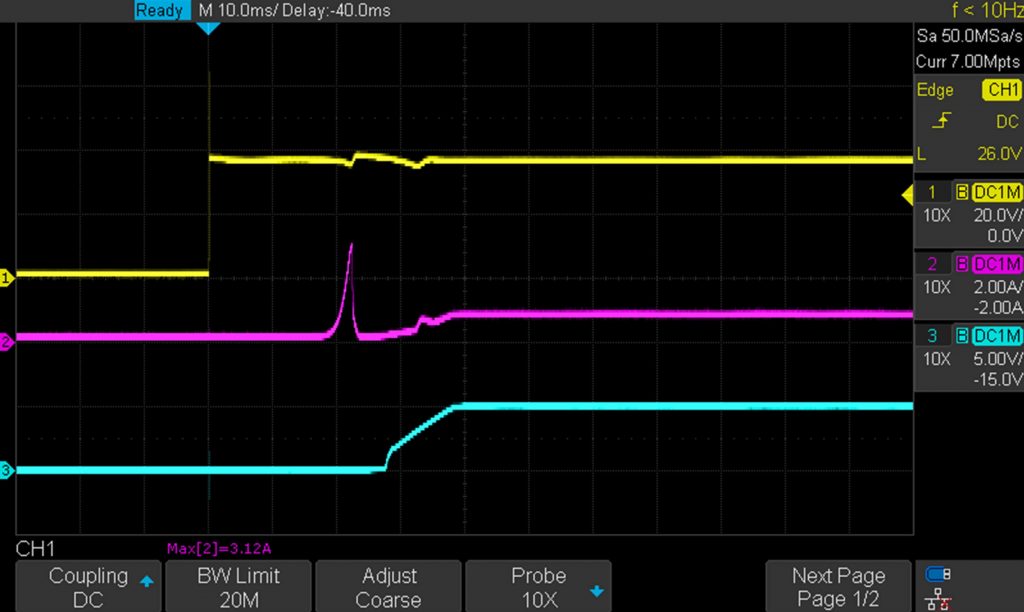

To overcome the problem, the EC7BW18-ECRT/EDRT has a built-in active inrush current limiter, which has higher efficiency performance with less impact from the ambient temperature when compared to a passive inrush current limiter (NTC). Figure 2a shows the inrush current of EC7BW18-72S05-ECRT with active inrush current limitation of 3.12A at input voltage 36Vdc. By contrast, when the inrush current limiter is removed (Figure 2b), the inrush current of EC7BW18-72S05-ECRT is 27.6A. The effects of high inrush current are even more pronounced at higher input voltages.

| With Inrush Current Limiter | Without Inrush Current Limiter |

|  |

| CH1: Input Voltage | CH1: Input Voltage |

| CH2: Input Current | CH2: Input Current |

| CH3: Output Voltage | CH3: Output Voltage |

| Figure 2a | Figure 2b |

Hold-up Circuit – Supply Interruption

In railway power systems, it is common to see the input supply voltage see short term fluctuations due to disturbances within the generator, battery, or pantograph system. These can also cause short periods of open circuit or short circuit at the input. EN50155 power supply tests simulate the interruptions of voltage supply and supply change-over, and are categorized into the following different classes:

Interruptions of voltage supply:

Class S1: No voltage interruption. No performance criterion is requested but the equipment shall continue to operate as specified after the voltage interruption.

Class S2: Interruption time 10ms.

Class S3: Interruption time 20ms.

Supply change-over:

Class C1: At 0.6*Vin during 100ms (without interruptions).

Class C2: During a supply break of 30ms stating at Vin.

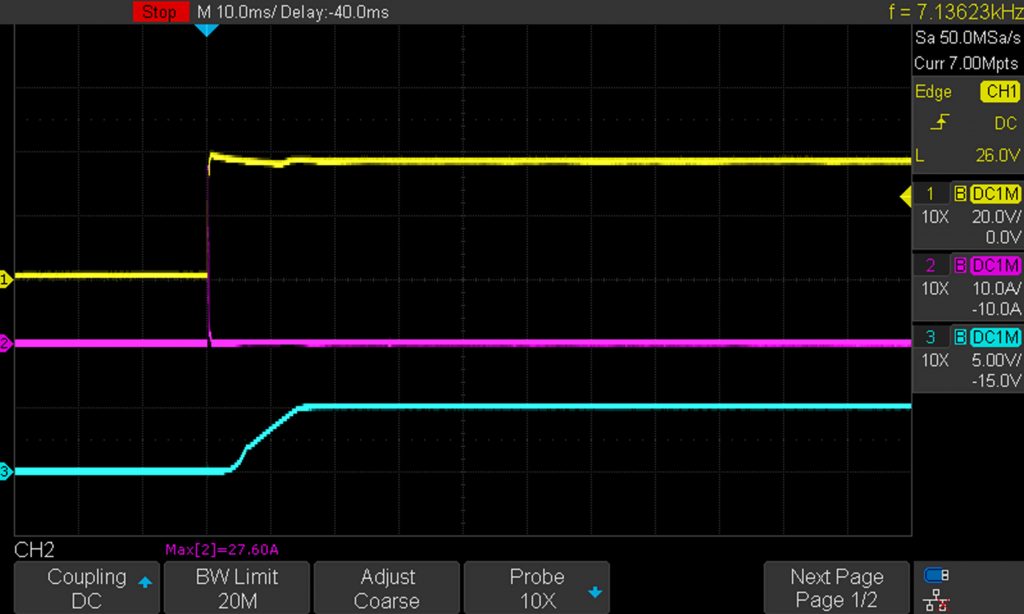

In order to meet the requirements of S2, S3 and C2, additional capacitance in required at the input side of the dc dc converter. The capacitance value can be determined by the formula below:

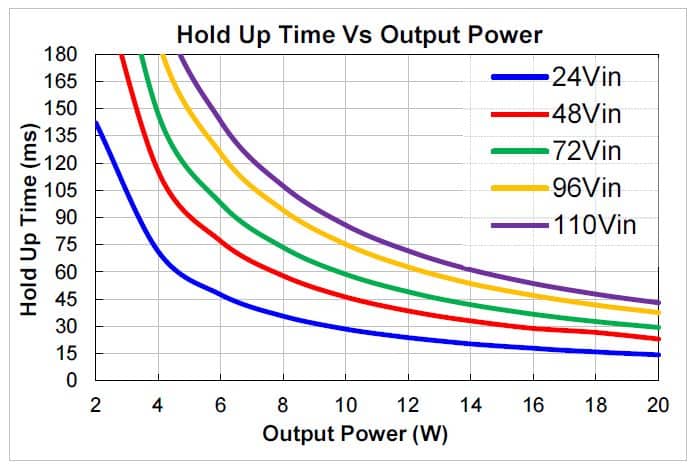

The constraints of this formula show that when the input voltage is lower, the required capacitance value will be higher; conversely when the input voltage is higher, the working voltage of the capacitors also needs to be higher. The EC7BW18-ECRT/EDRT has a hold-up circuit which meets the requirements of S2, S3* and C2***. Figure 3 shows the relationship of actual hold up time v output power for different traction input voltages.

Figure 3:

* S3 limit @ 24V < 14W, ** C2 limit @ 24V < 10W, *** C2 limit @ 48V < 15W

Additional Features

The EC7BW18-ECRT/EDRT modules are fully protected against misuse and over stressed operation. As standard they feature reverse polarity protection, over temperature protection (unit switches off at Tcase > 106 degrees), Over current protection (short circuit and overload), Input under voltage protection (prevents very high input current at low Vin) and output over voltage protection (secondary protection against an internal feedback failure).

Conclusion

Cincon’s goal when creating the EC7BW18-ECRT/EDRT was to create an “all-in-1” 20W power solution suitable for the system engineers as well as board level designers. The family has be developed around he proven EC7BW18-72 series 2” x 1” dc dc converters, with the addition of a rugged case and additional components they are able to offer a solution meeting all of the requirements of EN50155, EN50121-3-2 (EMC) and EN45545-2 as a single entity.

20W Turnkey Solutions

EC7BW18 ECRT/EDRT Series

Input: 10-160V dc- Single range

Outputs: 5V to +/-24V dc

Power: 20 Watt

Tamb: –40°C to +100°C

Dims: 4.45″ x 2.33″ x 0.68″ (113 x 59.2 x 21.6mm)

3000V ac Isolation

EC7BW18-72 Series

Input: 8.5-160V dc- Single Range

Outputs: 5V to +/-24V dc

Power: 20 Watt

Tamb: -40°C to +105°C

Dims: 2.0″ x 1.0″ x 0.4″

3000V ac Isolation

OTHER CONVERTERS FROM CINCON

GET IN TOUCH TODAY – 01929 555700

Here at Relec Electronics, we have worked closely with our key suppliers for over 40 years. We specialise in many industries, including; automotive, industrial, transportation, instrumentation & defence. We have a team of dedicated engineers ready to support you throughout the design process. We also carry stock of all standard modules and accessories for next day delivery.

Let’s make this easy and call us today.

Follow us on Facebook, LinkedIn & Twitter for updates on all of the latest Power Conversion products.

Sign up to our monthly newsletter below, and never miss out on our updates of industry news, we release news/blog pages weekly with news from the power and display industries.

Relec Electronics holds the highest standards towards finding you the ideal solution for your application. We truly believe “Standard is Just the Beginning”. Get in touch with our technical team today.

sign up for our newsletter

Enter your email address below

LET’S MAKE THIS EASY. CALL 01929 555 700

why choose relec?

-

Faster

Our aim is to get back to you with an initial response within the hour.

-

Attention to detail

We pride ourselves on getting you the right product, at the right price and on time.

-

New ideas

We are constantly looking for latest technology and products for your applications.

-

Beyond standard

It’s not just about the product. Our service goes way beyond the norm.

-

Easy

We want to make your life as simple as it can be. Call us to find out what we can offer.