How to take TFT glare out of the spotlight

19th May 2022How to take TFT glare out of the spotlight

We all spend huge parts of our lives now in front of TFT displays, be they our office workstations, mobile phones, checkout terminals, or even the humble television set. The majority of these have one thing in common; we use them indoors. Using a TFT display outside though brings a new set of challenges, especially in direct sunlight where the glare created from direct sunlight can make TFT display very difficult to read. This article takes a short look at 2 techniques to make TFT displays more readable in bright conditions.

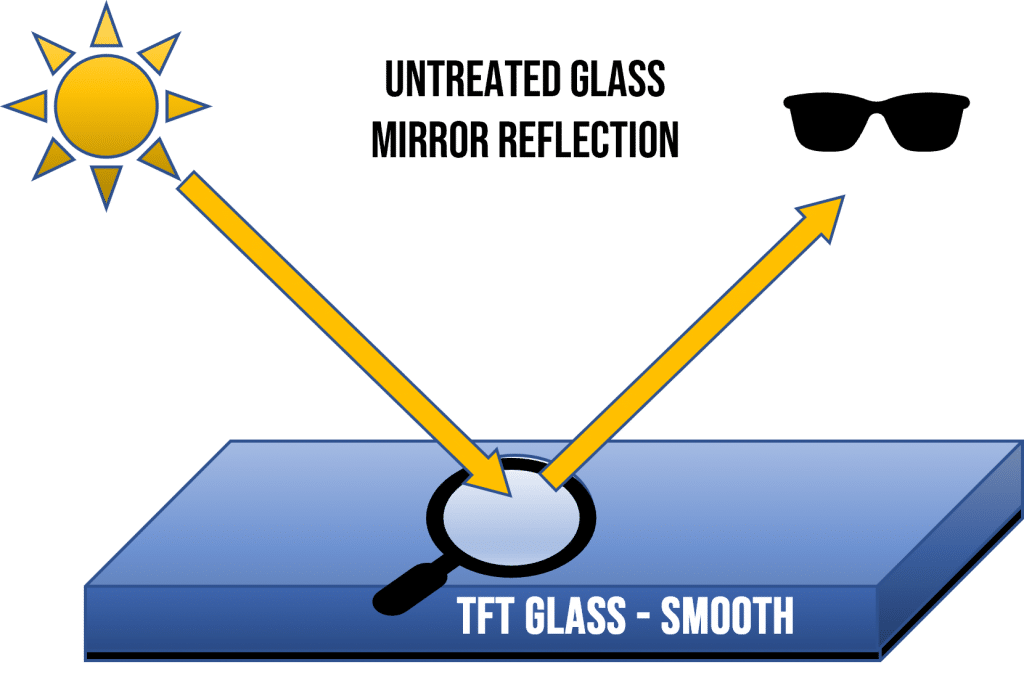

The Problem – Mirror Reflection

An untreated piece of TFT glass will exhibit many of the properties of a highly polished mirror. Incident light from the surroundings will be reflected from the glass surface (known as specular reflection) at the same angle it hits the display and making it extremely difficult to clearly read the image on the screen. This is especially prevalent in outdoor applications, where the glare from the sun’s rays can make a screen unreadable.

We will investigate 2 common techniques that can be applied so information is not lost, even on the brightest of days.

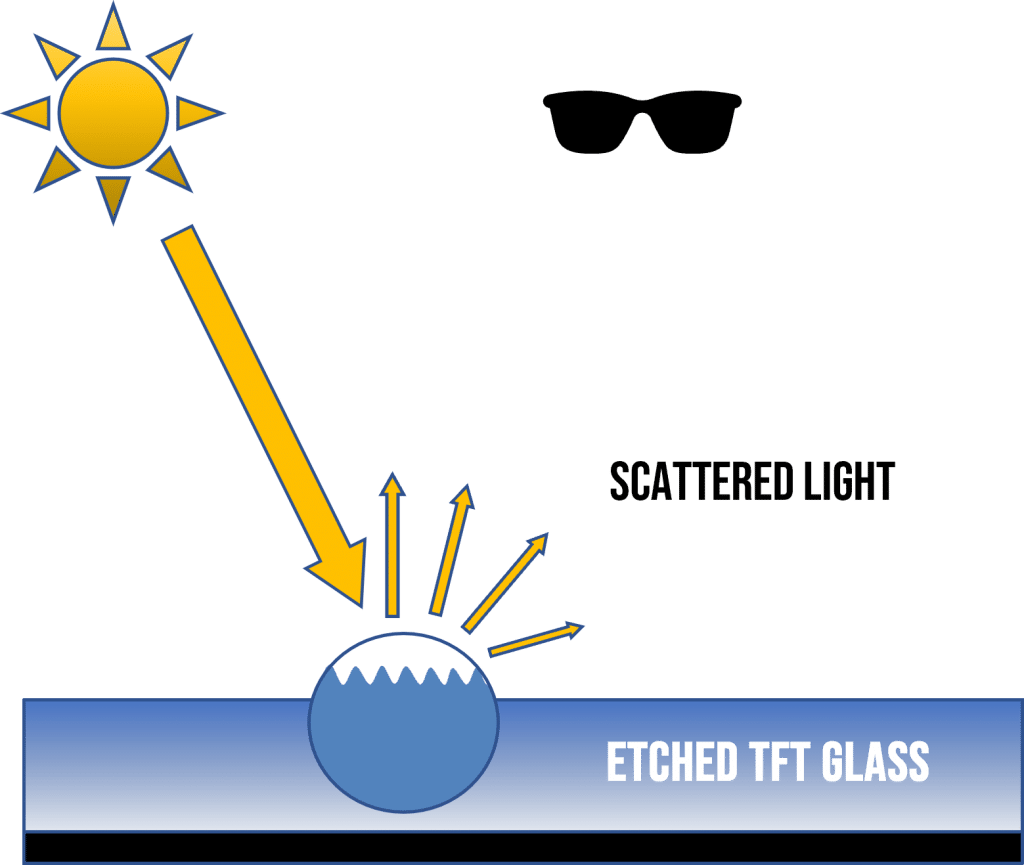

Solution 1 – Anti-Glare Etching

The etching process involves a solvent that incorporates hydrofluoric acid. This is applied to the cover glass – either one-sided or both to create an uneven surface which helps to diffuse or scatter the reflected light waves.

Advantages of this process include:

- Maintains the same hardness level as the original assembly

- The optical properties provides excellent uniformity (gloss value) across the full surface area optimising backlight performance.

- Provides a higher light transmission level which improves the visual brightness, compared to other methods.

- The result produces a strong and durable finish, which is unlikely to need replacing.

Some disadvantages of this process include:

- Due to the nature of this process, it can only be applied to a glass, which restricts where it can be used. For example, we are unable to use etching with a resistive touch panel.

- It is a more difficult and time-consuming process, resulting in higher prices compared to other methods.

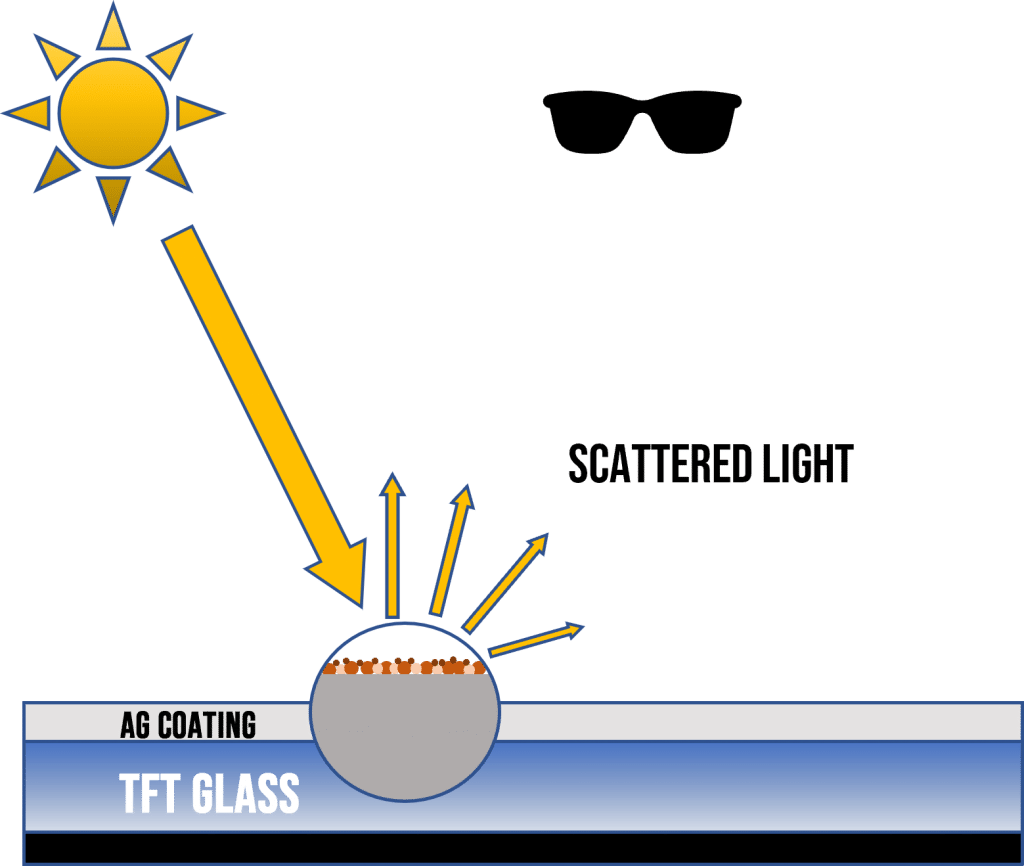

Solution2 – Anti-Glare Coatings

An anti-glare coating creates a similar effect by spraying the top cover lens with optical micro-particles which will also cause the incoming light to be scattered.

Advantages of this process include:

- A much easier and less timely process to apply.

- Can be applied to any surface material.

- A more cost-effective solution.

Disadvantages of AG coatings include:

- Coatings can cause a matte effect and a poorer gloss uniformity than etching.

- Slight impact on light transmission, which can reduce the visual brightness.

- Durability not as good as etching, and the coating may need replacing. With enough contact or force, the coating can peel off.

Both processes have their own advantages making them suitable for different applications. Etching, for example, works best in applications where the optical properties are of the highest importance (Marine instrumentation, Access control etc), or where the top surface will be under direct contact with something, ie when a touch panel is used. Whereas a coating process is best suited for indoor applications, but still under bright light conditions (Vehicle-based, operating theatres, factories etc), or where resistive touch panel technology has been selected.

Design Support

Relec offers a wide selection of TFT Displays, touch panels, Panel PCs and single-board computers (SBCs), suitable for applications from commercial grade to automotive and military. Relec’s experienced engineers are here to help you find the best solution for your application.

We consider ourselves experts in display technology. We have worked closely with our key suppliers for over 40 years. We specialise in many industries, including; automotive, industrial, transportation, instrumentation & defence. We have a team of dedicated engineers ready to support you throughout the design process. We also carry stock of all standard modules and accessories for next day delivery.

GET IN TOUCH TODAY – 01929 555700

Here at Relec Electronics, we have worked closely with our key suppliers for over 40 years. We specialise in many industries, including; automotive, industrial, transportation, instrumentation & defence. We have a team of dedicated engineers ready to support you throughout the design process. We also carry stock of all standard modules and accessories for next day delivery.

Let’s make this easy and call us today.

Follow us on Facebook, LinkedIn & Twitter for updates on all of the latest Power Conversion products.

Sign up to our monthly newsletter below, and never miss out on our updates of industry news, we release news/blog pages weekly with news from the power and display industries.

Relec Electronics holds the highest standards towards finding you the ideal solution for your application. We truly believe “Standard is Just the Beginning”. Get in touch with our technical team today.

sign up for our newsletter

Enter your email address below

LET’S MAKE THIS EASY. CALL 01929 555 700

why choose relec?

-

Faster

Our aim is to get back to you with an initial response within the hour.

-

Attention to detail

We pride ourselves on getting you the right product, at the right price and on time.

-

New ideas

We are constantly looking for latest technology and products for your applications.

-

Beyond standard

It’s not just about the product. Our service goes way beyond the norm.

-

Easy

We want to make your life as simple as it can be. Call us to find out what we can offer.