EN60945 Dissected

17th January 2023EN60945 Dissected

Share This Post

Share This Post

What sets out EN60945 compliant monitors from the pack? Relec and Elgens explain what needs to be considered

Modern maritime vessels are packed with electronics for communications and control and navigation.

As marine equipment is subject to extremely harsh operating conditions, shipbuilders and end customers will usually reject untested products outright. Manufacturers whose products are not tested and certified by a reputable third-party will therefore find it extremely difficult to access the marine equipment market and acquire customers.

These requirements come together under IEC60945, an international standard which specifies minimum performance requirements for equipment in maritime applications, and defines methods of testing, and required test results for maritime navigation and radiocommunication equipment and systems. This includes:

- Shipborne radio equipment that will be used as part of the global maritime distress and safety system required by the International Convention for Safety of Life at Sea (SOLAS) and the Torremolinos International Convention for the Safety of Fishing Vessels.

- Shipborne navigational equipment required by SOLAS and the Torremolinos International Convention for the Safety of Fishing Vessels, as well as other navigational aids where appropriate.

- Other bridge-mounted equipment, equipment in close proximity to receiving antennas, and equipment capable of interfering with safe navigation of the ship and with radio-communications (EMC tests only).

Levels of testing included in EN60945 include a series of environment and EMC tests which have been chosen to demonstrate that electronic equipment will survive in these harsh environments.

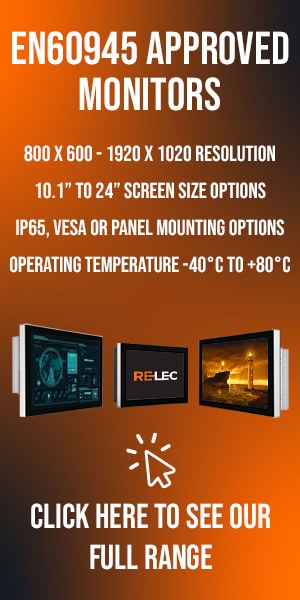

Relec offer a range of display solutions for the marine industry approved to IEC60945 & EN60945. Solutions include Panel PCs, monitors and discreet TFT display solutions. Module sizes range from 12.1” to 24”, with options for DNV compliance. Features include operating temperatures from -30°C to +80°C, high shock & vibration immunity, as well as rugged PCAP touch panels with excellent EMI/EMC performance.

Durability and Resistance to Environmental Conditions

Methods of testing and required test results

Prior to testing, the EUT should be visually inspected. After inspection, it should be preconditioned and mechanically and electrically checked. The requirements are listed in the EN60945 test specification. All tests shall be carried out with the equipment under test (EUT) in its normal operational configuration. This includes mounting and supports, and with all mechanical arrangements secure.

Dry Heat Test – IEC60068-2-2

The dry heat testing is a storage test and applies to portable, exposed and submerged equipment. This test simulates the effects of temperature stress on equipment while in the non-operating mode. A temperature of +70 °C is the maximum Iikely to be encountered. This covers equipment in enclosed spaces on ships and in equipment exposed to the full effects of solar radiation in ports.

Damp Heat Test – IEC60068-2-30

The damp heat testing applies to portable, protected and exposed equipment. This test determines the ability of equipment to be operated under conditions of high humidity. A single cycle is used with an upper temperature limit of +40 °C. This is the maximum that occurs in the earth’s surface atmosphere with a relative humidity of 93%

Low Temperature Test – IEC60068-2-1

The low temperature testing is a storage test applied to portable equipment. This test simulates the effects of temperature stress on equipment in the non-operating mode. It is applied to the portable equipment because of the importance that emergency equipment functions correctly after prolonged non-operation.

Elgens EN60945 monitors and panel PCs have been tested to operate over a range from -40 °C to +80 °C and relative humidity up to 93%.

Vibration Test – IEC60068-2-6

Based around the requirements of IEC60068-2-6, this test determines the ability of equipment to withstand vibration without resulting in mechanical weakness or degradation in performance over a range of 2 to 100Hz. The low frequency tests simulates the effect of vibration induced in a ship’s hull by its propeller and machinery. Tests at higher frequencies simulate the effect of slamming which occurs in irregular stormy seas.

Corrosion (Salt mist) Test - IEC60068-2-52

The corrosion testing or salt-mist testing is conducted in accordance with IEC60068-2-52 and applies to all equipment categories. The salt fog test determines the ability of an equipment to be exposed to a salt laden atmosphere without physical degradation. The cyclic nature of the test produces an acceleration of effects which can quickly degrade equipment, compared with service conditions.

EMC Testing

EN60945 provides general requirements for EMC standards of electronic navigation aids and shipborne radio equipment.

Conducted Emissions Test – CISPR 16-2-1 & 16-1-2

Conducted emissions testing applies to all equipment categories except portable. This EMC test measures any signals generated by equipment that appear on its power supply port and which can, therefore, be conducted into the ship’s power supply, and potentially disturb other equipment. These levels are considerably more stringent than commercial equipment (5 to 10dB lower) with tests extending down to 900Hz.

Radiated Emissions Test – CISPR 16-2-3

This EMC immunity test measures any signals radiated by equipment (other than through an antenna) which can potentially disturb other equipment on the ship, such as radio receivers. Again, this is more stringent than commercial standards with measurements starting at 150kHZ and high frequency limits being tighter above 200MHz.

Radiated Emissions Test – CISPR 16-2-3

The immunity to conducted radio frequency interference testing applies to all equipment categories except portable. This conducted immunity EMC test simulates the effects of disturbances induced in power, signal, and control lines from switching power supplies, engine ignition noise, echo sounders, and ships’ radio transmitters at frequencies below 80 MHz.

Immunity to Radiated Radiofrequencies Test – IEC61000-4-3

Immunity to radiated radiofrequency testing applies to all equipment categories except submerged. This radiated immunity test simulates the effects of radio transmitters at frequencies above 80 MHz, such as the ship’s VHF transmitter and hand-held portable radios, close to the equipment.

Immunity to Fast Transients - IEC61000-4-4

The immunity to fast transients on a.c. power, signal, and control lines apply to all equipment categories except portable. This radiated immunity EMC test simulates the fast, low-energy transients produced by equipment switching which causes arcing at contacts.

Immunity to Surges - IEC61000-4-5

The immunity to surges on a.c. power lines testing applies to all equipment categories except portable. This surge immunity test simulates the slow, high-energy surges produced by thyristor switching on a.c. power supplies.

Immunity to Power Supply Short-Term Variation Test – IEC61000-4-11

Immunity to power supply short-term variation testing applies to all equipment categories except portable. This power immunity test simulates power supply variations due to large changes in load. It is additional to the tests under permanent power supply variation in extreme test conditions. This test does not apply to d.c. powered equipment.

Immunity to Power Supply Failure Test - IEC61000-4-11

The immunity to power supply failure testing applies to all equipment categories except portable. This EMC/EMI test simulates short breaks in the ship’s power supply due to power supply changeover and breaker drop-out. This test does not apply to EUT intended for operation from battery power sources or fitted with or connected to backup batteries. It covers the break allowed by the IMO SOLAS Convention for changeover between main and emergency power supplies.

Immunity to Electrostatic Discharge Test – IEC61000-4-2

The immunity to electrostatic discharge testing applies to all equipment categories except submerged. This ESD immunity test simulates the effect of electrostatic discharges from personnel which may occur in environments that cause them to become charged, such as contact with artificial fiber carpets or vinyl garments.

Elgens EN60945 approved Monitors & Panel PCs have been designed using the highest quality components and fully tested and certified to all of the requirements listed above.

GET IN TOUCH TODAY – 01929 555700

Here at Relec Electronics, we have worked closely with our key suppliers for over 40 years. We specialise in many industries, including; automotive, industrial, transportation, instrumentation & defence. We have a team of dedicated engineers ready to support you throughout the design process. We also carry stock of all standard modules and accessories for next day delivery.

Let’s make this easy and call us today.

Follow us on Facebook, LinkedIn & Twitter for updates on all of the latest Power Conversion & Display products.

Sign up to our monthly newsletter below, and never miss out on our updates of industry news, we release news/blog pages weekly with news from the power and display industries.

Relec Electronics holds the highest standards towards finding you the ideal solution for your application. We truly believe “Standard is Just the Beginning”. Get in touch with our technical team today.

SHARE

sign up for our newsletter

Enter your email address below

LET’S MAKE THIS EASY. CALL 01929 555 700

why choose relec?

-

Faster

Our aim is to get back to you with an initial response within the hour.

-

Attention to detail

We pride ourselves on getting you the right product, at the right price and on time.

-

New ideas

We are constantly looking for latest technology and products for your applications.

-

Beyond standard

It’s not just about the product. Our service goes way beyond the norm.

-

Easy

We want to make your life as simple as it can be. Call us to find out what we can offer.