Bi-Directional Converters are the Driving Force for MHEVs

12th March 2021Bi-Directional DC-DC Converters are the Driving Force for MHEVs

Increased electronics content in vehicles and the rise in adoption of electric powertrains in vehicles has led to an increased interest in bi-directional DC-DC converters to manage the different power loads between 12V and 48V batteries. This article explores the background to, and need for bi-directional DC-DC converters in Mild Hybrid Electric Vehicles (MHEVs).

Bi-directional DC-DC converters are ideal for both industrial and automotive applications. This article discusses the changing landscape of automotive design and the role of DC-DC converters, and bi-directional models in particular. It considers the contribution they make to energy-efficient, long range hybrid electric vehicles as well as efficiently manage the vehicle’s internal communication bus for infotainment and comfort settings as well as transmission systems.

Since the early 2000s, with the addition of the in-vehicle navigation systems, the electronics content in vehicles has steadily growing. Increasingly sophisticated audio systems, infotainment and onboard computer systems mean that vehicles consume more power than earlier models. It is therefore economically feasible to store the energy required for today’s driving experience, in 48V batteries and for it to be converted to 12Vdc as and when required.

It may sound counter-intuitive to add another power system to a vehicle, where space is at a premium and the weight of a car affects performance, yet adding a 48V system to an existing 12V automotive electrical system does not require a total redesign.

Driving demand

Increased electrification of vehicles is also driving demand for 48V systems. A Lithium-ion battery is more efficient and can last up to 10 times longer than a lead-acid battery. They also significantly increase the driving range of a vehicle, with a Lithium-ion batteries typically having capacity of 150 to 250 Wh/kg, compared with 30 to 70 Wh/kg for a lead-acid battery. They are also able to handle more charge cycles than lead-acid batteries, allowing more cycles per unit and are capable of fast charging, up to 100% in 30 minutes. Lithium-ion batteries also weigh up to 75% less than their lead-acid counterparts and can be stored in any position, making integration more flexible.

The combination of the benefits of Lithium-ion batteries and SELV requirements found in bi-directional DC-DC converters has led to them being specified more frequently. They are now becoming mainstream in 48Vdc electrical systems which need larger energy storage and faster charging times.

Charge times of the Li-ion batteries are also much shorter than those of lead-acid batteries. As a result, adding 48V battery banks to an existing 12V system for energy storage is now feasible and cost-effective.

Mild hybrid electric vehicles

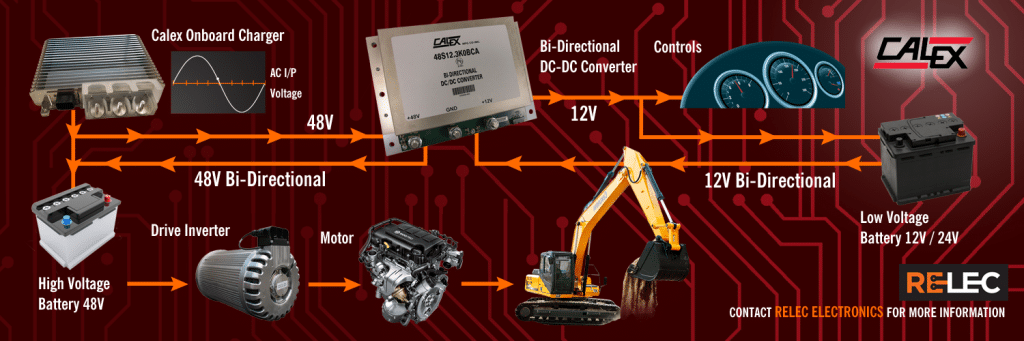

Mild hybrid electric vehicle (MHEV) architectures use the internal combustion engine (ICE) with a 48V electric system, or powertrain, to augment the engine and components in converting the engine’s power into movement. MHEVs use an electric motor to support the ICE during acceleration and when the vehicle is cruising.

The 48V battery serves the vehicle’s active chassis, electric steering, air conditioning system, engine cooling, heated windscreen, the positive temperature co-efficient (PTC) heater – which provides a heat source in the absence of engine exhaust heat – and turbo charging.

A bi-directional DC-DC converter, sits between the 12V and 48V batteries. It is a key component in the operation of mild hybrid systems. 48Vdc electrical systems require large energy storage capacity and fast charge times. The converter charges the 48V battery pack while the car is driving. The alternator on the ICE supplies 12Vdc to the converter, which in turn converts the 12V to 48V and charges the 48V battery pack.

Buck-boost converter operation

The number of sensors integrated into even basic models continues to rise, together with passenger comfort systems (seat positioning and electric windows), as well as transmission and engine control systems which require in-vehicle communication. A controlled area network (CAN) is a serial communication bus developed to reduce the vehicle’s cable wiring, which contributes to the weight and therefore the performance and fuel efficiency of vehicles. A vehicle’s CAN allows the separate electronic control units (ECUs) to communicate with only a single pair of wires.

Although vehicle electrical systems are moving from 12Vdc to 48Vdc, some auxiliary electrical loads will remain at 12Vdc. Loads such as headlights, driving lights, interior lights, radios, infotainment, and computer systems still require a 12Vdc input and will need to be powered by a DC-DC converter that steps down the 48V battery voltage.

A conventional buck-boost DC-DC converter can operate in step-up (boost) or step-down (buck) mode, but can only manage power flow in one direction. The converter’s mode of operation is determined by the input voltage, compared to the output voltage.

A bi-directional DC-DC converter, however, has the capability to manage the flow of power in both directions between two DC sources (batteries). The operational mode is determined by the required direction of current flow.

Mobile Energy Storage

Let us look at an example based on a recreational vehicle (RV). Using the two-way current flow capabilities of a bi-directional DC-DC converter, a 48V battery system can easily be added to a standard 12V system. While the RV is being driven, the 12V electrical system will charge the auxiliary 48V battery pack using the bi-directional converter in the boost (step-up) mode. While the RV is parked, the converter can be directed to change operation to a buck (step-down) converter and power the 12V accessories and appliances in the RV.

Another example is in recreational marine environments. Here too, the different modes of operation of a bi-directional DC-DC converter can be optimized to ensure the 48V battery can supply power to the 12V electrical system

Powering the 12V batteries from the 48V auxiliary battery extends the amount of time the boat’s auxiliary loads such as GPS, depth finders, trolling motors, radios, and refrigerators can operate.

As with the RV example, an auxiliary 48V battery system can be added to the existing 12V electrical system on these marine applications.

Regenerative Braking

Efficiency is extremely important in electric and hybrid architectures because it has a direct correlation to the vehicle’s range; the more efficiently the vehicle (or RV or boat) operates, the longer range it will have. One way to minimize, or lessen, losses and thus improve the efficiency of the vehicle is by recovering energy used to propel the vehicle.

Conventional traction or dynamic braking systems expend excess energy as heat. In contrast, regenerative braking recovers energy. It slows down a moving vehicle by converting its kinetic energy into energy that can be used immediately or stored until needed.

Battery Equalization

Another challenge for power system designers developing MHEV systems. When both 12V and 24V loads are connected, the lower battery will supply power to the 12V and 24V loads, and the top battery will only power the 24V loads. This will drain the lower battery faster than the top one. Balancing the two batteries extends the operating lifetime of each battery.

Battery equalizers actively transfer energy between two batteries to maintain each at the same voltage levels. It will balance (or equalize) the charge and discharge of the two batteries, but in order to balance the charge currents between both batteries, an equalizer must have the ability to change current directions. A battery equalizer is a version of a bi-directional DC-DC converter. It has specialized programming and circuitry to handle the requirements of balancing the charge and discharge currents of each 12V battery.

Bi-Directional DC-DC Converters

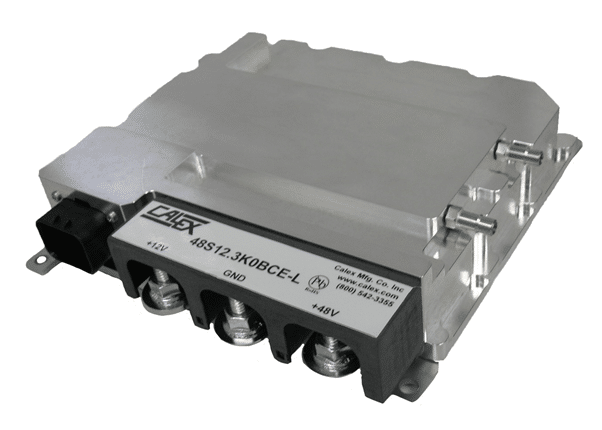

In response to the requirements outlined above, Calex has developed the 48S12.3K0BCA bi-directional DC-DC converter (Figure 1). The 3,000W chassis-mount, non-isolated DC-DC converter is designed for in-vehicle power distribution with 12V/48V battery configurations. This versatile DC-DC converter can be used for a variety of applications including micro and mild hybrid automotive systems.

[Figure 1: The 48S12.3K0BCA Series by Calex is a typical example of a bi-directional controller used in MHEV power systems.]

It charges a low side (12V) battery during normal operation (buck mode) and charges or assists the high voltage (48V) battery in emergency situations (boost mode). The 48S12.3K0BCA operates as an ideal current source with variable direction, allowing energy transfer between two voltage domains. Voltage feedback maintains the output voltage within the acceptable operating range and eventually allows a custom charging profile for the battery pack. It regulates the average current that flows between the high voltage and low voltage ports in the direction selected via a CAN interface.

The 48S12.3K0BCA Series is packaged in a low profile mechanically enclosed package which weighs typically just 1.37kg. The package makes the DC-DC converter suitable for use in the challenging automotive environment which has harsh shock and vibration requirements. It also facilitates integration with a battery pack. Three M8 bushings are provided, two for power connection and two for ground connections. Efficiency is up to 97% and it has over-current, over-voltage, and over-temperature protection. All protection functions are latching. The 48S12.3K0BCA has 12Vout (nominal) and a range of 6-18V. Calex also offers the 48S24.3K0BCA, 24V out (nominal) model (18-30Vout).

Calex has also developed the 3,000W BCE bi-directional, non-isolated DC-DC converter for in-vehicle power distribution with 12V/48V battery configurations. It is supplied in a low profile, IP67-rated liquid cooled or air cooled enclosure.

(The ingress protection (IP rating) is a guide to the level of protection offered by the DC-DC converter by an electrical enclosure, against solids and liquids. The 6 denotes that it is dust-tight, with zero ingress of dust permitted, 7 means it is protected against the effects of immersion between 15 cm and one meter for up to one hour.)

Like the BCA series bi-directional DC-DC converters, the 48S12.3K0BCE, 48S24.3K0BCE and 24S12.3K0BCE models charge a low side (12V) battery in buck mode and charges, or assists, the high voltage (48V) battery in emergency situations (boost mode). They operate as an ideal current source with variable direction, to allow energy transfer between two voltage domains. Voltage feedback maintains the output voltage within the acceptable operating range and eventually allows a custom charging profile for the battery pack. It regulates the average current flowing between the high voltage and low voltage ports in the direction selected via a CAN interface.

The BCE series (Figure 2) consists of the 48S12.3K0BCE, 48Vin (nominal), 12Vout (nominal) (24-58Vin and 6-18Vout); the 48S24.3K0BCE, which has the same input range and 12Vout (18 – 30Vout); and the 24S12.3K0BCE, which has 24Vin (18-30Vin) and 12V (6-18Vout). The package is suitable for the harsh shock and vibration conditions as well as saves valuable weight in the space-constrained automotive chassis.

Calex has also developed the 3,000W BEQ series, which ensures that battery voltages remain equal, to significantly extend the life of the battery life and provide the most cost-effective and dependable solution for dual voltage systems. It is also supplied in an air-cooled, IP-rated enclosure, offering high power density, 24Vin, 12V out for automotive 12/24V systems.

The company has also announced that it will add to its portfolio with a range of 4kW bi-directional converters for higher voltage applications as well as a 7kW 400 & 800V solution for on board chargers.

The Calex range of DC-DC bi-directional converters is available from Relec Electronics. Relec Electronics is a specialist in power conversion and display products, representing leading brand names including Bel Power, Chinfa, Cotek and Premium with key display partners, Digiwise and RockTouch.

For over 40 years, Relec Electronics has worked closely with key suppliers and specialises in a wide range of industry sectors, including automotive, industrial, transportation, instrumentation and defence.

A team of dedicated engineers is ready to support customers throughout the design process. The company carries stock of all standard modules and accessories for next day delivery.

Relec’s team of specialist advisers can refine an initial specification for a given application to include bespoke features to meet the needs of a particular design or project. In December 2020, Relec Electronics became a UK subsidiary of Gresham Worldwide.

GET IN TOUCH TODAY – 01929 555700

Here at Relec Electronics, we have worked closely with our key suppliers for over 40 years. We specialise in many industries, including; automotive, industrial, transportation, instrumentation & defence. We have a team of dedicated engineers ready to support you throughout the design process. We also carry stock of all standard modules and accessories for next day delivery.

Let’s make this easy and call us today.

Follow us on Facebook, LinkedIn & Twitter for updates on all of the latest Power Conversion products.

Sign up to our monthly newsletter below, and never miss out on our updates of industry news, we release news/blog pages weekly with news from the power and display industries.

Relec Electronics holds the highest standards towards finding you the ideal solution for your application. We truly believe “Standard is Just the Beginning”. Get in touch with our technical team today.

sign up for our newsletter

Enter your email address below

LET’S MAKE THIS EASY. CALL 01929 555 700

why choose relec?

-

Faster

Our aim is to get back to you with an initial response within the hour.

-

Attention to detail

We pride ourselves on getting you the right product, at the right price and on time.

-

New ideas

We are constantly looking for latest technology and products for your applications.

-

Beyond standard

It’s not just about the product. Our service goes way beyond the norm.

-

Easy

We want to make your life as simple as it can be. Call us to find out what we can offer.