WE CAN HELP – CALL NOW

01929 555 700

Panel PC

15″ IP66/69K Panel PC

Industrial

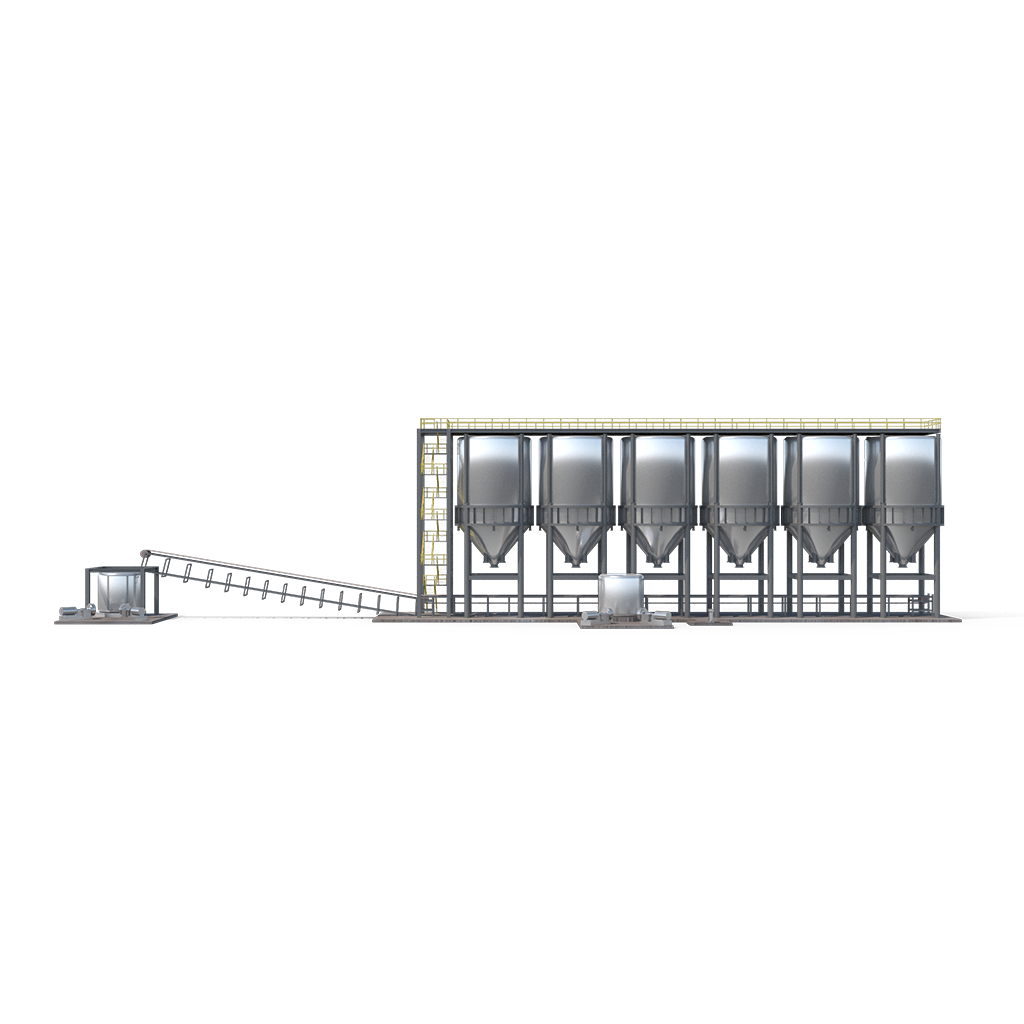

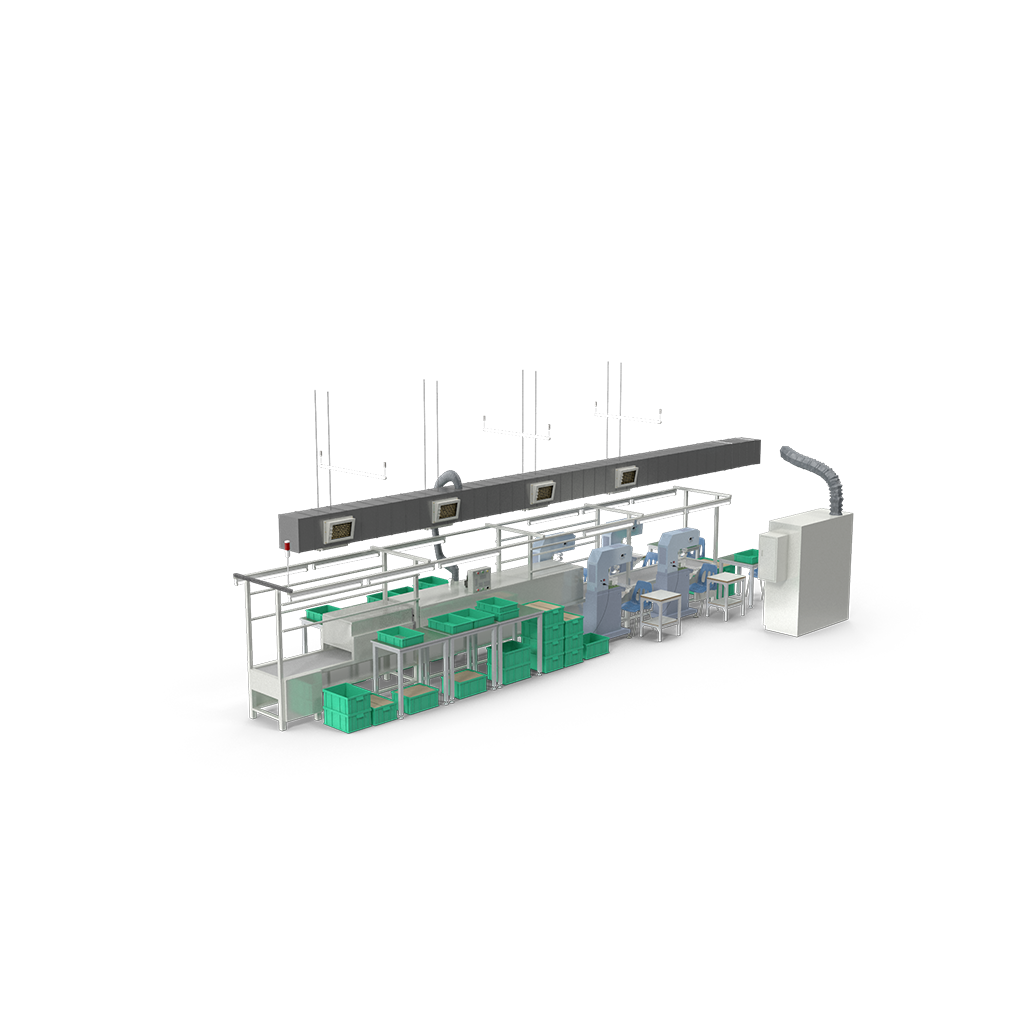

We were first contacted by a process engineer working for a UK-based dairy producer. Their production line was undergoing a digital overhaul, and they needed an industrial Panel PC to monitor and control critical stages of pasteurisation, packaging, and cleaning cycles.

Their current system consisted of a mix of outdated touchscreens and consumer-grade PCs housed in protective enclosures — which were no longer coping with the strict hygiene and high-pressure washdown demands of the environment.

The client’s must-haves included:

We recommended the 15″ IP66/69K Panel PC, from Wincomm, which ticked every box:

After a detailed consultation, we advised them to consider a panel-mount option with M12 connectors, as these provide an extra layer of ingress protection and simplify cable management on their swing-arm mounting system. We also supplied an optional anti-glare film, which would help visibility under the factory’s bright overhead LED lighting.

Our experts also walked them through BIOS settings and remote power control, ensuring the system could be rebooted and diagnosed without needing to open any cabinets — ideal during routine cleaning or shutdown.

The client deployed the washable panel pcs across their production line, each replacing a legacy setup that previously required regular maintenance.

Thanks to the 15″ IP66/69K Panel PC rugged design, the maintenance team no longer has to open enclosures to dry out moisture, and the end users on the factory floor (operators and QC staff) report clearer visuals and easier interaction, even in gloves.

Reach out to our expert team. Let’s start a conversation today!