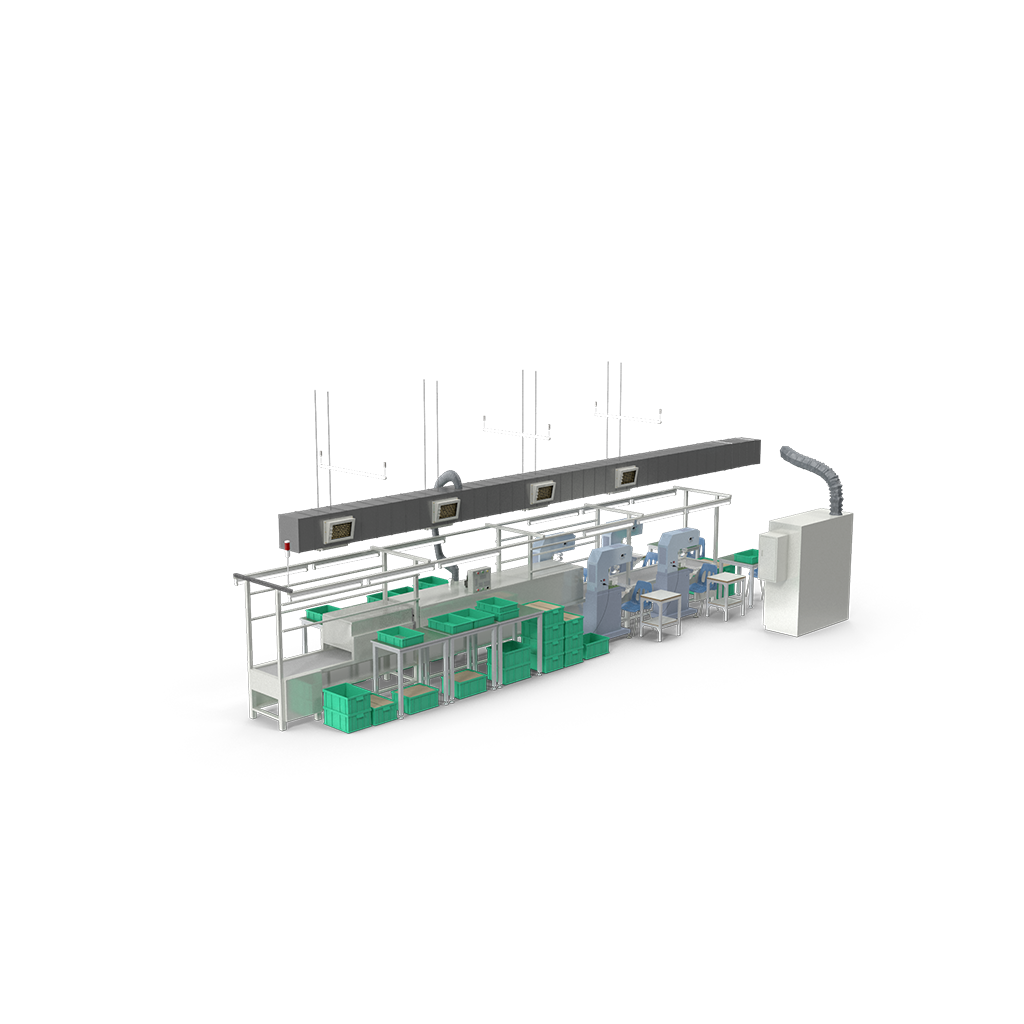

The solution was deployed to monitor multiple zones in a high-throughput factory. Using high-performance cameras and

edge AI, the system could detect abnormal activity, ensure SOP compliance, and prevent collisions in real time. Alerts were transmitted instantly to safety supervisors and control systems.

Thanks to DFI’s in-house OOB, the customer also gained full remote access to update BIOS, retrieve logs, or recover the OS — even if the system was powered off or had crashed. The result? 24/7 uptime with minimal on-site intervention.