WE CAN HELP – CALL NOW

01929 555 700

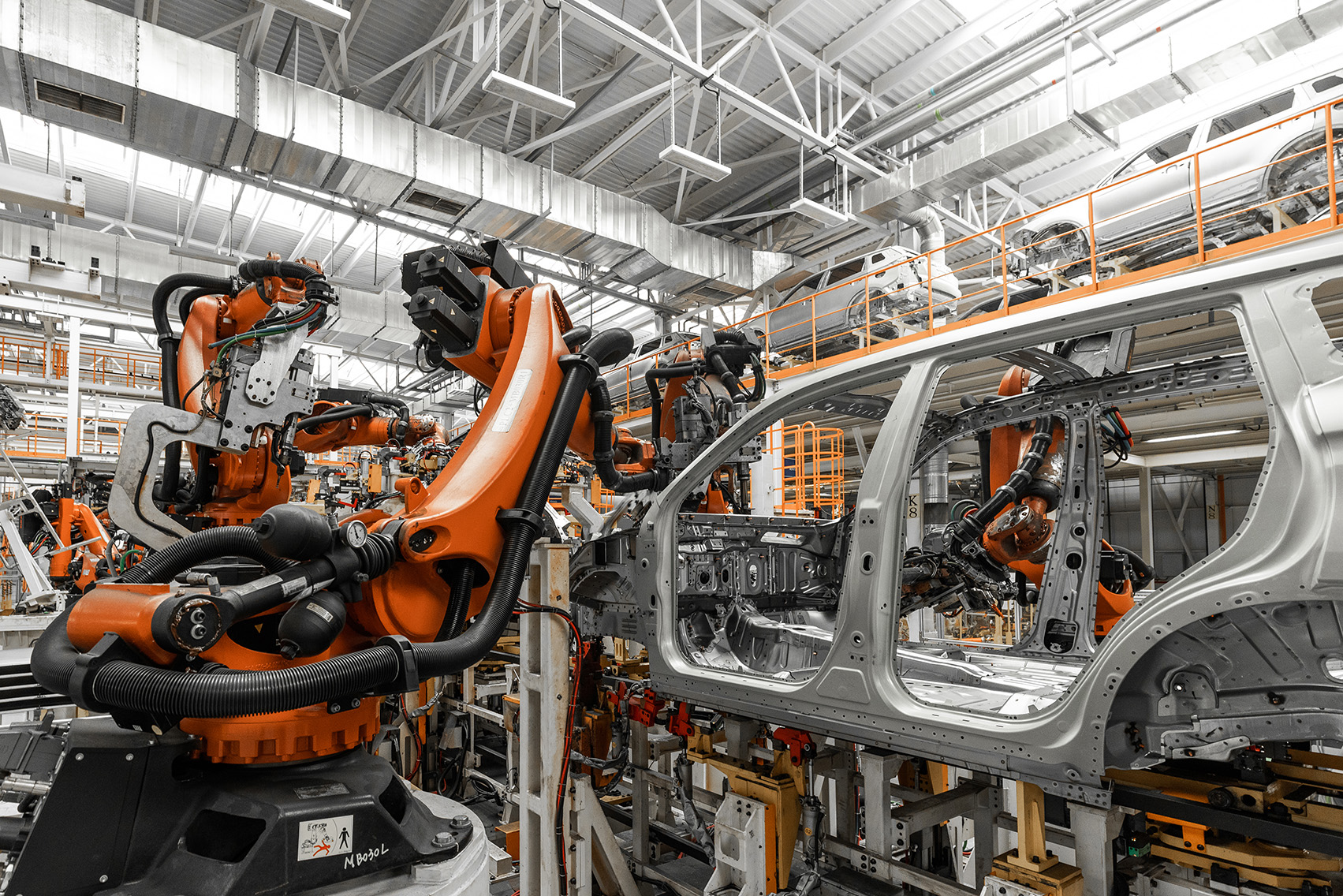

In modern industrial automation, manufacturers are under pressure to increase productivity, reduce downtime, and improve quality control. Achieving this requires powerful Edge AI systems that can run real-time analytics directly on the factory floor. These solutions must also be rugged and have high MTBF, with fanless designs to provide high level of ingress protection against, dust, moisture or other contaminants; whilst reducing vibration and temperature extremes. One of our customers needed exactly this for their next-generation smart manufacturing deployment.

Our customer, a leading manufacturer in the automotive supply chain, needed to deploy AI-enabled visual inspection and predictive maintenance systems across multiple production lines. The requirements were stringent:

They needed more than just a rugged PC. They needed a complete fanless Edge AI solution for industrial automation that could scale with their operations.

Relec recommended the MiTAC MX2-10ADP Fanless Edge AI Embedded System, designed specifically for industrial AI applications. Powered by a 65W Intel® Core™ i9 processor and MiAi-H8 AI accelerator card, the system delivers up to 208 TOPS of AI edge computing performance within a fully fanless architecture. This eliminated ingress-related failures and further improves reliability by keeping CPU temperatures low and eliminating all moving parts.

Relec’s engineering team provided additional value by:

By combining rugged hardware with application-specific support, Relec ensured the system was deployment-ready from day one.

The fanless Edge AI system transformed our customer’s production performance:

The customer summed it up best:

“Relec supplied us with a system that they made sure it would work in our environment, right from day one. Their technical input saved us time and ensured we got it right first time.”

This case highlights how Relec’s expertise in rugged embedded computing and Edge AI solutions supports industrial automation customers with reliable, scalable systems designed for real-world environments.

Reach out to our expert team. Let’s start a conversation today!